3D Printer Nozzle Size Guide:

0.2mm vs 0.4mm vs 0.6mm

Domechy Documentation Library | DCY-08

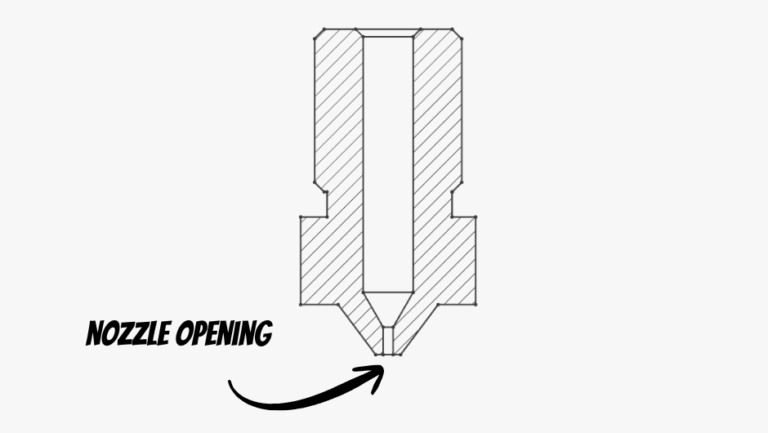

What is nozzle size?

In FDM 3D printing, nozzle size refers to the diameter of the opening where molten filament exits the hotend. This single parameter directly controls how much plastic is deposited per second. As a result, nozzle size has a measurable impact on print detail, print time, part strength, and reliability.

Most consumer 3D printers ship with a 0.4 mm nozzle because it offers the best overall balance between quality and speed.

0.2 mm nozzle: Prioritizing detail

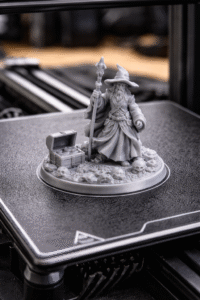

A 0.2 mm nozzle extrudes very thin lines of filament, which allows the printer to reproduce fine surface details and small features more accurately. This is why it is commonly used for miniatures, small mechanical parts, or decorative prints.

However, because the extrusion width is narrow, the printer must make many more passes to build the same object. This increases print time significantly and also raises the risk of clogging, especially if the filament contains dust or additives.

Typical characteristics:

- Layer height usually between 0.08–0.16 mm

- Print time can be 2–3× longer than 0.4 mm

- Weaker layer bonding compared to larger nozzles

Use a 0.2 mm nozzle when visual quality matters more than speed or strength.

0.4 mm nozzle: The standard choice

The 0.4 mm nozzle is considered the industry default for consumer FDM printers. It offers enough resolution for most designs while maintaining good print speed and reliable extrusion.

From a mechanical perspective, this nozzle size provides a good compromise: extrusion lines are thick enough to bond well between layers, but still fine enough to preserve most surface details. This is why slicer profiles and filament manufacturers typically optimize their settings around 0.4 mm.

In practice, a 0.4 mm nozzle:

- Supports layer heights of roughly 0.12–0.28 mm

- Works well with common materials like PLA, PETG, and ABS

- Has the lowest failure rate for most users

If you are unsure which nozzle to choose, 0.4 mm is the safest and most versatile option.

0.6 mm nozzle: For speed and strength

A 0.6 mm nozzle extrudes significantly more material per second. This increases volumetric flow, which shortens print time and improves layer adhesion. For large or functional parts, this often results in stronger prints with fewer layer separation issues.

The trade-off is reduced resolution. Small text, sharp corners, and thin walls may lose definition or fail to print as intended.

Common characteristics:

- Layer height typically 0.24–0.48 mm

- Print time reduced by 30–50% compared to 0.4 mm

- Better suited for large parts and structural components

Choose a 0.6 mm nozzle when speed and mechanical strength are more important than surface detail.

How to choose the right nozzle size

A simple way to decide is to match the nozzle size to your print goal:

- High detail, small objects → 0.2 mm

- Everyday prints, general use → 0.4 mm

- Fast, strong, large parts → 0.6 mm

From a physics standpoint, larger nozzles improve inter-layer bonding due to higher material flow, while smaller nozzles improve geometric accuracy by reducing extrusion width. You cannot maximize both at the same time.