PLA vs PETG:

3D Printing Filament Guide for Beginners

Domechy Documentation Library | DCY-07

PLA vs PETG: Which 3D Printing Filament Should Beginners Choose?

If you are new to 3D printing, two filament types will appear very quickly: PLA and PETG.

Both are widely used, affordable, and supported by most FDM 3D printers. However, they behave very differently.

This guide explains the practical differences so beginners can choose the right filament with confidence.

What is PLA?

PLA (Polylactic Acid) is a bioplastic made from renewable plant-based sources, mainly corn starch or sugarcane.

PLA is often described as biodegradable, but this is commonly misunderstood.

Important clarification

PLA does not naturally degrade in normal home or outdoor environments.

Actual biodegradation requires industrial composting conditions, typically:

- Temperature around 58–65 °C

- Controlled humidity and microbial activity

In landfills or nature, PLA can remain intact for many years, similar to conventional plastics.

So while PLA is bio-based, it is not automatically environmentally friendly in real-world disposal.

PLA – Key Characteristics

- Printing temperature: 190–220 °C

- Bed temperature: 0–60 °C (optional)

- Warping: Very low

- Odor: Minimal

- Surface finish: Smooth

PLA – Pros

- Easiest filament for beginners

- Very high print success rate

- Excellent dimensional accuracy

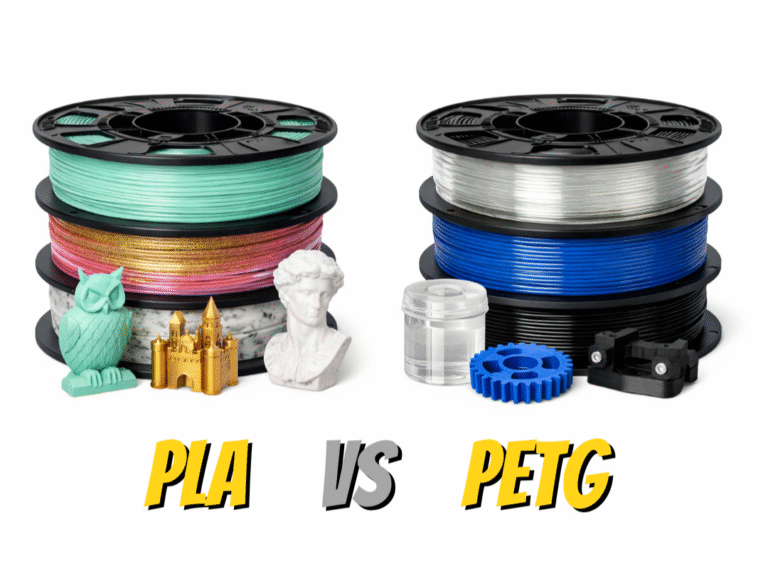

- Extremely wide range of colors and finishes

PLA supports more pigments and additives than most filaments.

Common or PLA-dominant color/finish examples

- Pastel colors (mint, lavender, baby blue)

- Silk PLA (gold, copper, dual-color silk)

- Marble PLA

- Gradient / rainbow PLA

- Fluorescent / neon PLA

- Wood-filled PLA

Many of these are rare or unreliable in PETG due to higher printing temperatures.

PLA – Cons

- Low heat resistance (softens around 55–60 °C)

- Brittle under impact

- Not suitable for outdoor use or high-load parts

When Should You Use PLA?

PLA is best used for indoor, low-stress applications where appearance matters more than strength or heat resistance.

Typical PLA use cases

- Decorative items and display models

- Desk organizers

- Figurines and toys (non-mechanical)

- Prototypes for checking size and fit

- Indoor mounts or holders away from heat

Example

A phone stand on your desk, a cable organizer, or a decorative robot model are ideal PLA applications.

What is PETG?

PETG (Polyethylene Terephthalate Glycol-modified) is derived from PET, the same plastic used in drink bottles, with glycol added to improve printability.

Unlike PLA, PETG is not biodegradable, but it is chemically stable and water-resistant.

PETG – Environmental Note

- PETG does not biodegrade

- It is recyclable only where compatible PET recycling systems exist

- Environmental impact depends largely on waste handling, not material type alone

PETG – Key Characteristics

- Printing temperature: 220–250 °C

- Bed temperature: 70–90 °C

- Warping: Low

- Odor: Minimal

- Surface finish: Glossy

PETG – Pros

- Stronger and more impact-resistant than PLA

- Better heat resistance (~75–85 °C)

- Water and chemical resistant

- Suitable for functional and outdoor parts

PETG – Color & Finish Reality

PETG supports fewer specialty finishes compared to PLA.

Common PETG options:

- Solid colors

- Transparent or translucent filaments

- Mild glossy finishes

Rare or difficult in PETG:

- Silk finishes

- Pastel tones

- Wood-filled blends

- Strong color gradients

This is due to higher extrusion temperatures, which limit pigment stability.

PETG – Cons

- Stringing is common

- Bed adhesion can be too strong

- Requires more tuning than PLA

When Should You Use PETG?

PETG is better suited for functional parts that need durability, water resistance, or moderate heat tolerance.

Typical PETG use cases

- Outdoor brackets or mounts

- Bathroom or kitchen accessories

- Tool holders

- Mechanical parts with light load

- Parts exposed to sunlight or moisture

Example

A wall hook in the bathroom, an outdoor sensor enclosure, or a tool holder near a window are better printed in PETG than PLA.

PLA vs PETG – Quick Comparison

| Feature | PLA | PETG |

|---|---|---|

| Ease of printing | Very easy | Moderate |

| Strength | Low–medium | Medium–high |

| Heat resistance | Low | Medium |

| Outdoor use | No | Yes |

| Color variety | Very wide | Limited |

Which Should Beginners Choose?

Start with PLA.

PLA consistently offers:

- Higher success rate

- Faster learning curve

- More aesthetic options

Move to PETG when you need:

- Stronger parts

- Water or heat resistance

- Outdoor durability